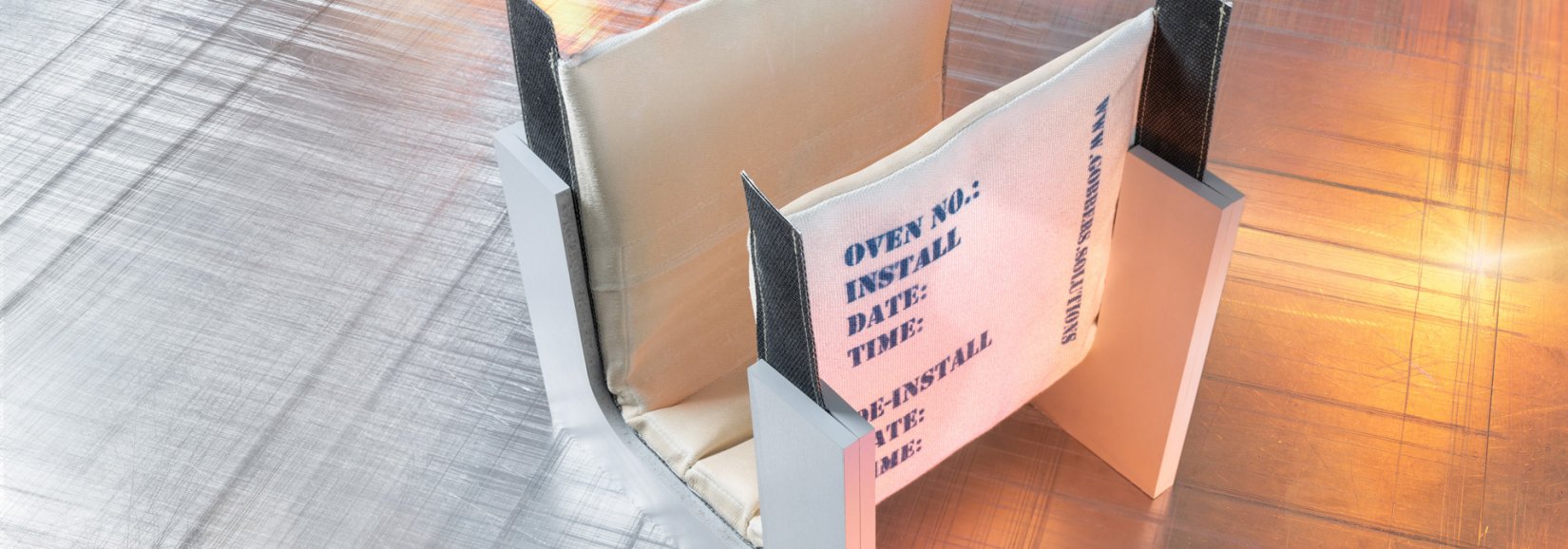

A mechanical and thermal, process-safe connection

In a foundry, extreme mechanical and thermal conditions prevail especially between the casting furnace and casting drain system.

By a tilting motion the hot liquid aluminium melt from the casting furnace will be poured into the distribution channel system with around 700 degrees Celsius.

Our flexible launder joints ensures a thermal, mechanical and process-safe connection between the casting furnace and the distribution channel system at this point.

The fabrics used by Gobbers Solutions are processed with multi-layers and are made from high-quality fabrics. They are resistant to temperatures up to 1000 degrees Celsius and the inside lying mat has a temperature resistance up to even 1100 degrees Celsius.

Features and benefits

- mechanical and thermal, process-safe connection between casting melting furnace and distribution channel system

- High-quality and individually tailored material composition

- low dead weight

- Savings of time and cost-intensive maintenance measures and service inspections

- Extended maintenance cycles

- quick and safe assembly and disassembly

- Multiple use

- long durability